Key Takeaways

- A wiring harness is an organized assembly of wires, connectors, and insulation that streamlines the transmission of power and signals in machines and electronic systems.

- Wiring harnesses are essential in industries such as automotive, consumer electronics, and industrial machinery, offering improved safety, reliability, and simplified installation.

- Key components of a wiring harness include wires and cables, connectors and terminals, and protective sheaths, all selected to match specific application requirements.

- The use of wiring harnesses reduces electrical shorts, enhances performance, facilitates maintenance, and ensures compliance with industry safety standards.

- Designing wiring harnesses involves challenges like component compatibility, space constraints, environmental protection, electrical load management, regulatory compliance, and customization for specific needs.

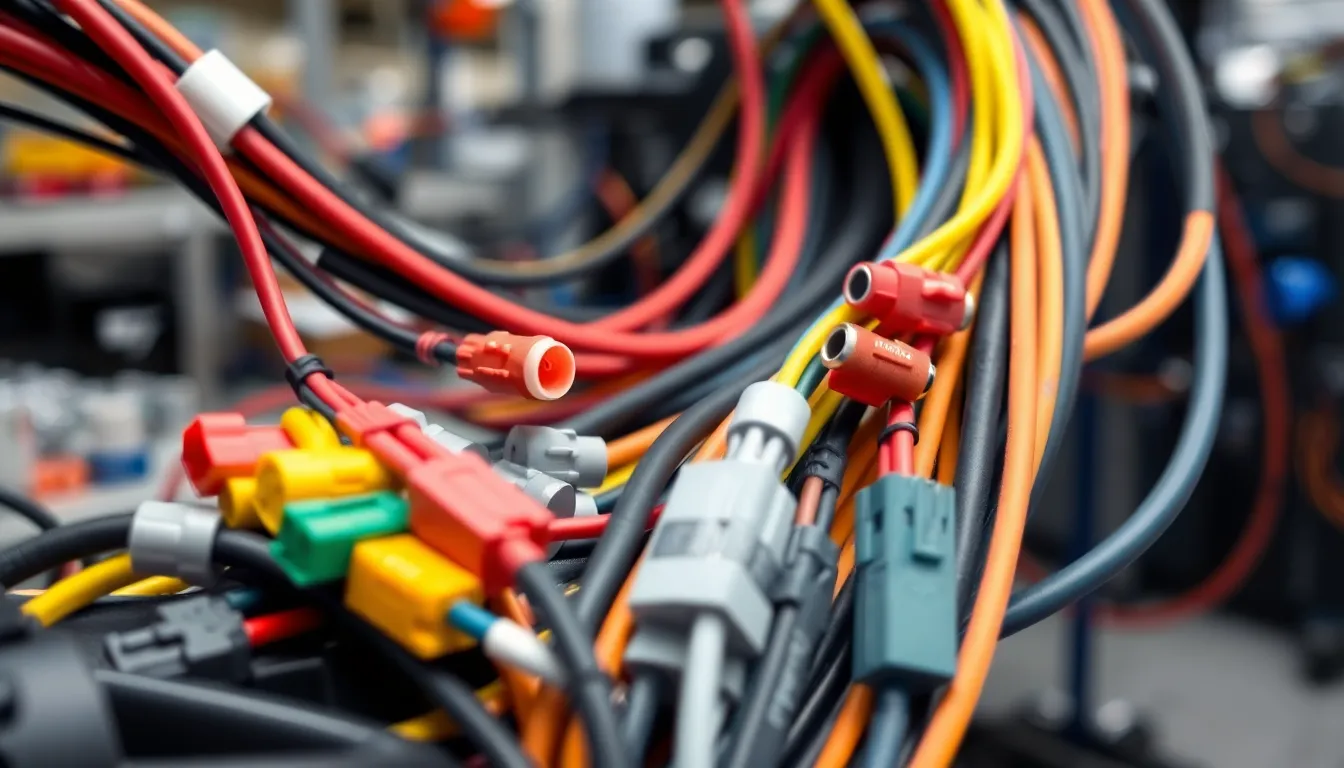

Modern machines and vehicles rely on complex networks of wires to function properly. A wiring harness organises these electrical connections by bundling wires, connectors, and insulation into a single assembly that streamlines power and signal transmission. Companies like Cloom Tech manufacture custom wiring harnesses for automotive, industrial, and medical applications, improving safety, reliability, and simplifying installation processes.

What Is a Wiring Harness?

A wiring harness is an organized assembly of electrical wires, terminals, and connectors that transmits power and signals between components in a machine or electronic system. Engineers use wiring harnesses to group and secure cables, which simplifies installation and reduces the risk of electrical shorts by protecting wires from vibration, moisture, and abrasion.

In automobiles, wiring harnesses route power to headlights, ignition systems, and electronic control units. In industrial equipment, these assemblies handle critical signal transmission for sensors and actuators. Cloom Tech in Florida manufactures custom wiring harnesses that meet exact specifications for automotive, robotics, medical device, and aerospace applications.

A standard wiring harness includes labeled wires, high-quality insulation, and connectors chosen for electrical compatibility and mechanical durability. Cloom Tech selects wire gauges, connector types, and protective sheathing based on system voltage, current requirements, and application environment. By integrating these elements, Cloom Tech improves production speed, enhances device reliability, and ensures compliance with industry safety standards.

Key Components of a Wiring Harness

A wiring harness combines several standardized parts to support secure electrical transmission in complex assemblies. Cloom Tech in Florida integrates precise component selection for durability and compatibility in automotive, industrial, and medical device harnesses.

Wires and Cables

Wires and cables carry electrical power and signals in a wiring harness. Manufacturers use specific gauges and conductor materials—usually copper or aluminum—for optimal current capacity. In automotive applications, harnesses route power for ignition, lighting, and control modules. For robotics and medical electronics, designers specify shielded cables to block electromagnetic interference and maintain stable data signals. Cloom Tech sources wires with distinct color codes and insulation ratings to meet UL and ISO standards.

Connectors and Terminals

Connectors and terminals join wires to devices and control units in the harness. Individual harnesses may use pin terminals, ring terminals, or multi-pin connectors for secure electrical contact. In automotive wiring harnesses, manufacturers use waterproof connectors for engine bays and instrument clusters. Industrial harnesses employ heavy-duty terminals for motor control systems. Cloom Tech manufactures custom connector assemblies for aerospace and robotics, ensuring tight mechanical fit and reliable signal transfer in harsh environments.

Protective Sheaths and Insulation

Protective sheaths and insulation shield wires from abrasion, heat, and moisture. Harnesses often use PVC, Teflon, or braided coverings, depending on the application’s temperature and chemical exposure. Automotive harnesses require corrugated tubing or tape-wrapped bundles for vibration resistance. In medical devices, medical-grade insulation meets sterilization and biocompatibility requirements. Cloom Tech applies precision-jacketed sheathing and laser-marked insulation for clear identification and long-term function in demanding sectors.

Common Applications of Wiring Harnesses

Wiring harnesses support efficient power and signal distribution across multiple industries by consolidating connections and shielding wires from damage. Cloom Tech in Florida supplies custom solutions that improve reliability and simplify integration for manufacturers.

Automotive Industry

Wiring harnesses form the backbone of modern vehicles, supporting electronic and safety systems. Engineers route harnesses to manage power for systems such as ignition, lighting, airbag sensors, and infotainment units. Integrated harnesses optimize space in dashboards, engine compartments, and chassis, decreasing installation time by up to 70% compared to loose cables, according to SAE International. OEMs specify harnesses using industry standards like ISO 6722 for durability under vibration and temperature changes. Cloom Tech manufactures automotive wiring harnesses that meet abrasion resistance and moisture protection requirements, complying with FMVSS and quality certifications for North American vehicle production.

Consumer Electronics

Wiring harnesses enable compact device assembly and secure connections in televisions, computers, home appliances, and gaming consoles. Internal harnesses support efficient communication between circuit boards, displays, inputs, sensors, and battery modules. Device manufacturers use color-coded harnesses for error-free assembly and quicker quality checks during mass production. Harness construction complies with UL and RoHS standards for safety and environmental protection. Cloom Tech designs harnesses for consumer electronics that maintain shielding from EMI and fit within compact enclosures, delivering dependable electrical performance even with frequent device use.

Industrial Machinery

Wiring harnesses organize complex cabling for automated equipment, CNC machines, robotics, conveyor systems, and control panels. Industrial harnesses integrate power lines, Ethernet cables, sensor feedback, and pneumatic or hydraulic control signals into single assemblies, reducing connection errors and accelerating equipment maintenance. Engineers specify industrial harnesses with oil- and chemical-resistant sleeves and flame-retardant jackets, referencing standards such as UL 758 and IEC 60227. Cloom Tech provides custom harnesses for machinery manufacturers, supplying assemblies pre-labeled and tested for immediate installation, improving uptime in manufacturing operations.

Benefits of Using Wiring Harnesses

Organizing and Protecting Electrical Connections

Wiring harnesses organize multiple wires into a single assembly, reducing clutter and improving traceability in finished products. Grouped cables minimize risks of electrical shorts, physical damage, and tangling, especially in high-density environments like automotive or robotics systems manufactured by Cloom Tech in Florida.

Simplifying Installation and Maintenance

Bundled wires reduce installation time, as a single harness connects multiple circuits efficiently. Labeled and color-coded wires in Cloom Tech harnesses streamline error checks and speed up diagnostics, which lowers maintenance costs in industrial and medical devices.

Enhancing Performance and Reliability

Harnesses insulate and shield wires, protecting them from moisture, vibration, and abrasion. This protection extends the lifespan of electrical systems in aviation and automotive applications, ensuring consistent performance by maintaining stable signal and power transmission.

Improving Safety and Compliance

Pre-assembled harnesses eliminate exposed wires that could increase the risk of electrical faults or fires. Cloom Tech’s harnesses use materials certified for industry standards, helping manufacturers meet safety and regulatory requirements.

Supporting Scalability and Customization

Custom harnesses allow precise adaptation to specific device layouts, ensuring compatibility with evolving product designs. Cloom Tech engineers tailor harness lengths, connector types, and insulation materials to match project requirements for electronics, medical devices, and aerospace systems.

Challenges in Designing Wiring Harnesses

- Component Compatibility

Component compatibility in wiring harness design relates to matching wire gauges, insulation types, and connector specifications with equipment requirements. If incompatible parts are paired, issues like signal loss or overheating occur. Cloom Tech selects compatible materials using standardized testing to ensure consistent performance in critical systems.

- Space and Weight Constraints

Space and weight constraints restrict wiring harness layouts in industries like automotive and aerospace. Designers minimize bulk and optimize routing using flexible insulation and multi-conductor cables. Cloom Tech engineers customize harness geometries to fit complex assemblies, reducing installation time in confined spaces such as vehicle dashboards and medical device housings.

- Environmental Exposure

Environmental exposure impacts harness longevity, especially in systems facing moisture, heat, chemicals, or abrasion. Cloom Tech incorporates specialized jacketing, seals, and grommets to block contaminants and maintain signal integrity in harsh environments. Use cases include offshore equipment, engine compartments, and outdoor robotics.

- Electrical Load Management

Electrical load management defines harness performance in distributing power and signals without overheating. Engineers calculate circuit demands, select proper fusing, and apply current-carrying standards like IPC/WHMA-A-620. Cloom Tech documents load ratings for each harness to help prevent circuit failure in high-demand assemblies.

- Regulatory Compliance

Regulatory compliance applies to both material selection and assembly techniques. Product designers must align harness construction with standards like UL, ISO 9001, or RoHS. Cloom Tech’s quality assurance team certifies that harnesses meet regulatory mandates, supporting automotive, aerospace, and medical OEMs in audit and documentation procedures.

- Customization Requirements

Customization requirements drive complexity in wiring harnesses for specialized machinery, robotics, and medical systems. Engineers specify exact lengths, configurations, and marking systems, while Cloom Tech produces prototypes for design validation. Customers receive labeled wiring diagrams and serial-tracked batches for traceability and maintenance support.

| Challenge | Industry Example | Cloom Tech Solution |

|---|---|---|

| Component Compatibility | Automotive, Aerospace | Standardized Material Testing |

| Space and Weight Constraints | Automotive, Medical | Flexible, Optimized Routing |

| Environmental Exposure | Outdoor Robotics | Specialized Jacketing, Sealing |

| Electrical Load Management | Industrial Equipment | Load Documentation, Proper Fusing |

| Regulatory Compliance | Medical Devices, Aerospace | Certified Assembly, Audit Support |

| Customization Requirements | Robotics, Machinery | Prototyping, Traceable Production |

About Cloom Tech

Cloom Tech, located in Medley, FL, specialises in manufacturing custom wire harnesses and cable assemblies for various industries, including automotive, robotics, medical devices, and aerospace.

Led by spokesperson Ivy Zhao, Cloom Tech provides design support from prototype to production, ensuring the creation of high-quality, durable, and reliable wiring solutions. Their tailored services are designed to meet the unique requirements of each project, delivering precision-engineered products that exceed industry standards.

Contact:

Ivy Zhao, Spokesperson

Phone: +1 863 434 8447

Email: [email protected]

Address: 9251 NW 112th Ave, Medley, FL 33178, USA

Website: www.cloomtech.com

Frequently Asked Questions

What is a wiring harness?

A wiring harness is an organized assembly of electrical wires, connectors, and terminals that transmits power and signals between different parts of a machine or device, ensuring efficient and safe electrical connections.

Why are wiring harnesses important in vehicles and machines?

Wiring harnesses organize and protect electrical wires, preventing shorts and reducing the risk of damage from vibration, moisture, or abrasion. They ensure reliable power and signal distribution, supporting essential systems and improving device reliability.

Where are wiring harnesses commonly used?

Wiring harnesses are widely used in automobiles, electronic devices, industrial machinery, robotics, medical equipment, and aerospace, helping manage complex wiring needs and ensuring safety and efficiency in these applications.

What are the main components of a wiring harness?

The main components of a wiring harness include electrical wires or cables, connectors, terminals, protective sheaths, and insulation. Each part is selected and assembled based on the application’s electrical and environmental requirements.

How do wiring harnesses improve manufacturing efficiency?

Wiring harnesses simplify installation by grouping wires into bundles, making assembly quicker and reducing errors. Pre-assembled harnesses also facilitate easier maintenance, diagnostics, and replacements, saving time and cost during production and repairs.

What benefits do wiring harnesses provide over loose wires?

Wiring harnesses keep electrical systems organized, minimize clutter, and enhance safety by preventing exposed wires. Their insulation offers protection, increases reliability, and helps meet safety and regulatory standards in finished products.

How are wiring harnesses customized for different industries?

Manufacturers like Cloom Tech design custom wiring harnesses to fit specific layouts, environmental conditions, and electronic requirements, tailoring materials and configurations to meet the unique needs of industries such as automotive, medical, and aerospace.

What challenges are faced when designing wiring harnesses?

Designers must ensure component compatibility, manage space and weight constraints, protect against environmental factors, handle varying electrical loads, meet regulatory standards, and address the complexity of custom applications.

Why is it important to choose the right materials for a wiring harness?

Choosing suitable materials for wires, insulation, and connectors ensures durability, prevents electrical failures, withstands environmental challenges, and maintains compliance with safety and industry standards for each specific application.