Key Takeaways

- Pogo pin connectors are spring-loaded components that provide reliable, repeatable electrical connections in compact electronic devices.

- Their durable design supports high mating cycles (often over 50,000), making them ideal for frequent connection and disconnection scenarios like charging docks and test equipment.

- Pogo pins are widely used across consumer electronics, medical devices, and industrial applications for charging, data transfer, and secure docking.

- Key advantages include compact size, high conductivity (thanks to gold plating), resistance to vibration/shock, and customizable configurations.

- Key considerations when selecting a pogo pin connector include current rating, pin pitch/length, environmental sealing (e.g., waterproof options), and compatibility with manufacturing processes.

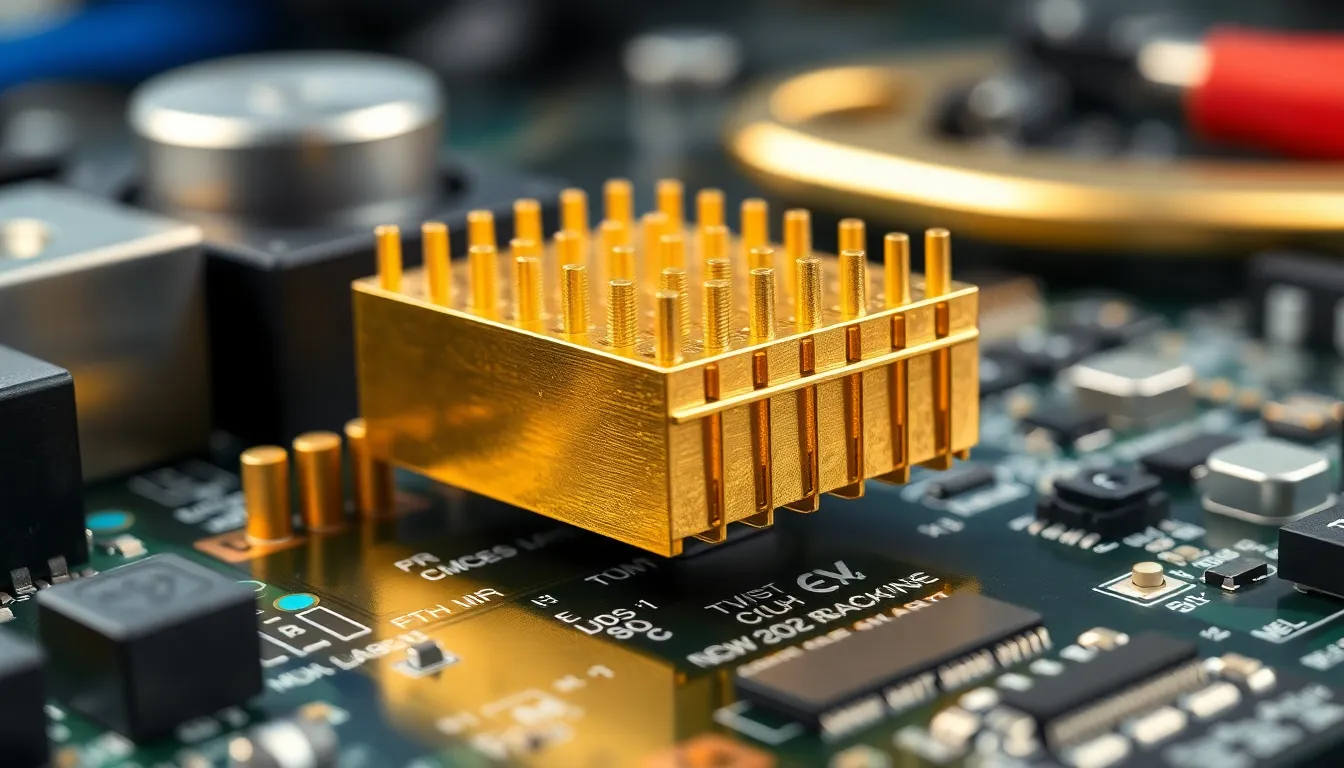

Pogo pin connectors are spring-loaded components that deliver reliable, repeatable electrical connections in compact electronic devices, supporting over 50,000 mating cycles for demanding applications. These versatile connectors are widely utilised across consumer electronics, medical devices, and industrial equipment for charging, data transfer, and secure docking solutions. Leading pogo pin connector manufacturer companies offer customisable configurations with gold plating, vibration resistance, and environmental sealing options to meet diverse industry requirements.

What Is a Pogo Pin Connector?

A pogo pin connector uses a spring-loaded pin to provide a stable, repeatable electrical connection between circuit boards and electronic modules. Spring-loaded pins apply consistent pressure, which improves contact reliability even with repeated mating cycles. Most pogo pin connectors consist of a plunger, barrel, and spring, all made from precision-machined brass or copper alloy with gold plating for enhanced conductivity.

Designers select pogo pin connectors when devices require compact, high-density connections—like battery charging ports, test points, or signal contacts in smartphones, wearables, and medical devices. Promax, based in China, manufactures pogo pin connectors with tolerances as tight as ±0.05 mm. Their products achieve over 50,000 mating cycles, meeting demands for long service life in consumer electronics and medical instruments.

Engineers can specify pin pitch, length, plating, and current rating. Promax supports custom configuration with options for waterproof sealing, SMT compatibility, and magnetic alignment features. Pogo pin connectors operate in temperatures from -40°C to 85°C. This versatility makes them essential for rapid test setups, docking solutions, and low-profile interconnects in modern device designs.

How Pogo Pin Connectors Work

Pogo pin connectors use a spring-loaded mechanism to create quick, stable electrical connections in electronic assemblies. Engineers in industries like consumer electronics, medical devices, and aerospace rely on these connectors to maintain consistent performance in tight spaces.

Key Components and Design

Core components of a pogo pin connector include the plunger, spring, barrel, and base. The plunger, made from precision-machined brass or copper alloy, makes contact with the mating pad. The spring sits inside the barrel, providing consistent force when compressed. The barrel holds the plunger and spring, ensuring smooth movement during each connection cycle. Promax manufactures pogo pin connectors using gold-plated surfaces for minimal resistance and corrosion protection, supporting high-cycle durability. Standard designs offer pin pitches from 0.4 mm to 3.0 mm and lengths from 2 mm to 20 mm to fit dense board layouts. Engineers can select custom shapes, magnetic alignment, or waterproof construction, depending on project requirements.

Electrical and Mechanical Operation

Pogo pin connectors operate by pressing the spring-loaded plunger against a mating contact pad, ensuring low-resistance current flow. The plunger compresses the internal spring, maintaining reliable force throughout repeated cycles. Maximum rated current for a single pin typically ranges from 1A to 5A, depending on pin diameter and material choice. Manufacturers like Promax specify spring force parameters from 30g to 200g to match mechanical needs. Gold-plated contact surfaces reduce signal loss, supporting high-speed transmission for data and power applications. The connector’s resilience—more than 50,000 mating cycles—makes it suitable for frequent connect/disconnect scenarios such as battery charging docks, programmable logic testers, and diagnostic equipment.

Common Applications of Pogo Pin Connectors

Pogo pin connectors support reliable, long-life electrical connections across compact assemblies. Engineers select them for high-density device charging, data transfer, and test applications in electronics and medical sectors.

Consumer Electronics

Pogo pin connectors serve as key interfaces in compact devices, including smartphones, smartwatches, fitness trackers, and wireless earbuds. Manufacturers use pogo pins for battery charging docks, data transfer pads, modular accessories, and magnetic charging ports. Promax produces standard and custom connectors with pin counts up to 100 and pitches as tight as 0.4 mm. Gold plating and tight mechanical tolerances enable stable electrical contacts and high mating cycles—often exceeding 50,000 operations per unit. Device OEMs choose pogo pins to enable fast charging and seamless modular connectivity where space is limited.

Industrial and Medical Devices

Pogo pin connectors play critical roles in medical diagnostic equipment, handheld scanners, electronic instrumentation, and docking stations. Design engineers rely on these connectors for applications demanding secure, repeatable mating and resistance to vibration or accidental disconnect. In medical environments, Promax supplies connectors sealed to IP67 or higher to ensure moisture resistance for sterilizable tools and portable monitors. Pin current ratings of 1A–5A support robust test jigs, patient monitors, and implantable device interfaces. Industrial automation uses pogo pin blocks to facilitate rapid fixture changes and minimize downtime in high-throughput production settings.

Advantages of Using Pogo Pin Connectors

Pogo pin connectors deliver stable electrical contact and reliable performance in high-frequency connection cycles. They support compact device assemblies by maintaining strong connections in minimal space. Spring-loaded design absorbs shock and vibration, allowing equipment like medical analyzers or handheld scanners to operate in challenging conditions.

Engineers benefit from pogo pins’ high mating cycle counts, with Promax connectors rated for over 50,000 cycles. Gold-plating on Promax springs and plungers prevents corrosion and sustains low electrical resistance, critical for smart device charging docks, hearing aids, and testing jigs.

Fast assembly and modularity distinguish pogo pin connectors from traditional soldered connections. Magnetic alignment, available in Promax solutions, accelerates device docking in wearables and industrial tools. IP-rated seals, offered by Promax, protect pins in humid, dusty, or sterilizable medical environments.

Customization options from Promax include adjustable pin pitch, barrel length, and current rating for application-specific needs in aerospace, smart home, and automotive fields. Consistently low and stable contact resistance (as low as 30mΩ) ensures efficient charge transfer across device generations.

| Feature | Benefit Example |

|---|---|

| High-cycle durability | >50,000 cycles in battery docks, test jigs |

| Reliable conductivity | Gold-plated pins in medical and consumer devices |

| Compact footprint | Low-profile connectors in smartwatches, trackers |

| Shock resistance | Stable connections in industrial sensors |

| Custom configurations | Specified pin layouts for automotive modules |

| Environmental sealing | Waterproof pins for sterilizable medical equipment |

| Fast mating/docking | Magnetic Pogo pins in hearing aids, wearables |

Considerations When Choosing a Pogo Pin Connector

Selecting a pogo pin connector depends on electrical, mechanical, and environmental factors. Engineers assess current and voltage ratings to match device requirements. For applications like medical analyzers and automotive modules, connectors with higher current ratings, such as Promax models supporting 5A or more, ensure safety and device reliability.

Pin pitch and length influence assembly compatibility. Smaller pitches, such as 0.4 mm, suit high-density PCB layouts, while longer pins, such as 20 mm, accommodate deep socket connections. Promax offers both standard and customized dimensions for unique electronic assemblies.

Mating cycle durability affects long-term performance in high-use environments. For devices requiring frequent connections, connectors rated for 50,000 or more cycles—as manufactured by Promax—offer extended service life. Gold plating supports low contact resistance and corrosion prevention, making it appropriate for humid or medical settings.

Environmental sealing, like IP67 waterproof ratings, prevents connector failure from dust or moisture. Promax produces pogo pin connectors with waterproof and magnetic alignment features to support secure assembly in challenging field conditions.

Mounting style—SMT, through-hole, or custom harness—impacts integration with manufacturing processes. Promax provides solutions compatible with automated surface mount assembly for consumer electronics and diagnostic tools.

Engineers consider custom options for magnet alignment, current carrying needs, or waterproofing when standard connectors don’t fit. Promax supports tailored manufacturing, rapid prototyping, and tight tolerances to match specific electronic component requirements.

About Promax Pogo Pin

Promax Pogo Pin specializes in manufacturing high-quality pogo pins, spring-loaded connectors, and magnetic connectors for consumer electronics, aerospace, and medical industries. With over 15 years of expertise, they provide customizable solutions, competitive pricing, and internationally certified quality standards. Whether it’s a standard connector or a custom design, they are equipped to deliver precision-engineered solutions for diverse applications.

Contact:

Gavin Yi, Director

Phone: (765) 705-7361

Email: [email protected]

Website: promaxpogopin.com

Location: 480 Jackson St, Gary, IN 46402, USA

Frequently Asked Questions

What is a pogo pin connector?

A pogo pin connector is a type of electrical connector that uses spring-loaded pins to establish quick, stable, and repeatable electrical connections between devices or circuit boards. They are commonly used for charging, data transfer, and testing in compact electronic devices.

How do pogo pin connectors work?

Pogo pin connectors work by pressing a spring-loaded plunger against a contact pad, which creates a low-resistance electrical connection. The spring ensures consistent contact pressure, making the connection stable and suitable for frequent connect/disconnect cycles.

Where are pogo pin connectors commonly used?

Pogo pin connectors are widely used in smartphones, smartwatches, wireless earbuds, medical devices, handheld scanners, and diagnostic equipment. Their durability and reliability in compact spaces make them ideal for high-density charging, data transfer, and modular accessories.

What are the main advantages of pogo pin connectors?

Key advantages include stable electrical contact, high durability (over 50,000 cycles), resistance to shock and vibration, corrosion resistance from gold plating, and compact design. They can also be customized for specific applications, including waterproofing and magnetic alignment.

What factors should be considered when choosing a pogo pin connector?

Important factors include current and voltage ratings, pin pitch and length, mating cycle durability, and environmental sealing (such as IP67 ratings for moisture protection). Customization options for your device’s size and requirements are also crucial.

What materials are typically used to make pogo pin connectors?

Pogo pin connectors are usually made from precision-machined brass or copper alloy and are often gold-plated. This material combination ensures high conductivity, durability, and resistance to corrosion.

How durable are pogo pin connectors?

High-quality pogo pin connectors, like those from Promax, can endure over 50,000 mating cycles, making them suitable for applications requiring frequent connections and disconnections, such as battery charging docks and test interfaces.

Can pogo pin connectors be customized for specific devices?

Yes, pogo pin connectors can be customized in terms of pin layout, pitch, length, current rating, waterproof sealing, magnetic alignment, and more. This ensures optimal fit and performance for different electronic devices and applications.

What is the typical current rating for pogo pin connectors?

Most pogo pin connectors are rated for maximum currents between 1A and 5A, which is sufficient for applications like battery charging and data communication in consumer and medical electronics.

Are pogo pin connectors suitable for harsh environments?

Yes, with features like shock and vibration resistance, moisture sealing (such as IP67 rating), and gold-plated contacts, pogo pin connectors perform reliably even in demanding or harsh environments found in medical, industrial, and automotive applications.