\

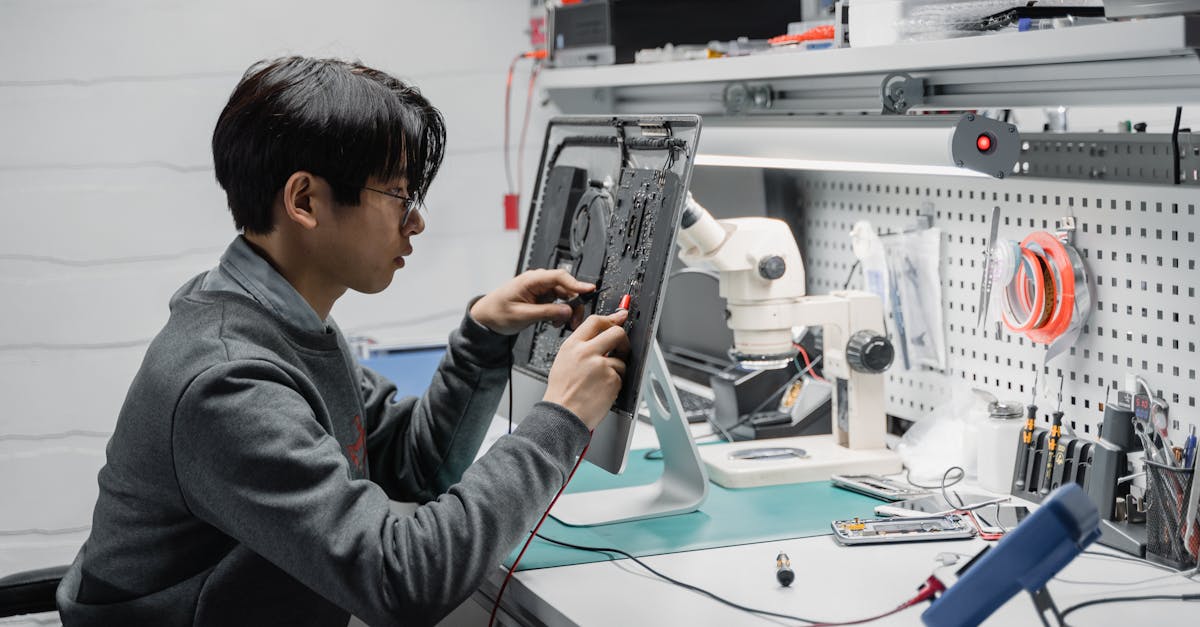

Photo by Tima Miroshnichenko on Pexels

Electronics keep getting smaller and more powerful, and double-sided PCB assembly manufacturers play a big role in making that possible. These experts craft printed circuit boards with components on both sides, allowing for more complex and efficient designs. As demand for high-performance electronics grows, choosing the right manufacturer becomes crucial for businesses aiming to stay ahead in a competitive market.

WellPCB Complete Guide to Custom PCB Fabrication Services provides comprehensive insights into modern double-sided PCB assembly capabilities and industry standards that define quality manufacturing practices.

What Is a Double-Sided PCB Assembly Manufacturer?

A double-sided PCB assembly manufacturer produces printed circuit boards with copper traces and mounted components on both sides of the substrate. This setup supports higher component density and improved circuit complexity for products like medical devices, automotive modules, and consumer electronics. Manufacturers design, fabricate, and assemble PCBs to client specifications, following standards such as IPC-A-610 and RoHS compliance.

Professional BGA PCB Assembly Manufacturing Services use automated surface mount technology (SMT) and through-hole assembly in double-sided PCB production. SMT allows precise placement of integrated circuits on either side, while through-hole techniques ensure secure mechanical connections for components exposed to elevated stress or power.

WellPCB Manufacturing Solutions Website supplies engineering support, prototyping, and high-volume double-sided PCB assembly services for global clients, ensuring consistent quality through in-line AOI (Automated Optical Inspection) and ICT (In-Circuit Testing). Advanced BGA PCB Assembly Solutions source certified materials, manage multilayer lamination, apply solder masks, and perform lead-free soldering.

Custom BGA PCB Assembly Manufacturing Typical production lines support rapid turnaround and scalable solutions for startups and established electronics brands seeking double-sided PCB assemblies.

Advanced Manufacturing Technologies and Process Innovation

Modern double-sided PCB assembly relies on sophisticated manufacturing technologies to achieve the precision and quality required for today’s electronics. WellPCB Manufacturing Process Demonstration illustrates how advanced automation systems integrate to create efficient, high-quality double-sided assembly processes.

Expert BGA PCB Assembly Services incorporate cutting-edge placement systems with precision alignment capabilities essential for double-sided assembly applications. These systems utilize advanced vision systems and real-time process monitoring to ensure optimal component placement on both PCB sides.

WellPCB Innovation Technology Showcase demonstrates how artificial intelligence and machine learning enhance double-sided assembly quality through predictive process control and automated defect detection systems that optimize production efficiency.

Specialized Assembly Solutions for Complex Applications

Double-sided PCB assemblies often incorporate specialized components requiring advanced assembly techniques. Low Volume PCB Assembly Manufacturing addresses the unique challenges of assembling components on both sides of PCBs while maintaining quality and reliability standards.

Professional Low Volume PCB Assembly services include specialized placement techniques, selective soldering processes, and comprehensive testing procedures that validate performance in double-sided configurations. These services are essential for ensuring optimal functionality across diverse applications.

Specialized Low Volume PCB Solutions support both prototype development and production runs for double-sided applications requiring precise component placement and reliable interconnections.

Key Benefits of Double-Sided PCB Assembly

Double-sided PCB assembly supports complex electronics by enabling circuit designers to place components and copper traces on both sides of the board. WellPCB Professional PCB Services Portal uses this technology to deliver advanced functionalities with efficient use of board space.

Enhanced Design Flexibility

Double-sided PCB assembly increases design options for electronics engineers. Components like microcontrollers, capacitors, and connectors can be distributed on both sides, eliminating restrictions from single-layer layouts. This capability supports intricate routing and denser component placement.

Custom Low Volume PCB Assembly Services process enables mixed technology assembly, combining surface mount and through-hole components. This flexibility benefits industries like medical devices or automotive modules where size, weight, and efficiency targets are strict. WellPCB Manufacturing Risk Elimination Excellence Quick prototyping lets design teams make layout adjustments early in development.

Improved Signal Integrity

Double-sided PCB assembly allows designers to optimize trace routing, reducing signal path lengths and cross-talk between channels. Placing ground planes and power planes on dedicated layers or splitting components strategically on each side lowers electromagnetic interference.

High Frequency PCB Manufacturing Excellence uses automated inspection, SMT, and quality checks to maintain signal integrity for high-speed circuits in communications, industrial, and consumer electronics. Specialized High Frequency PCB Services Boards assembled with controlled impedance and precise alignment help sustain higher data rates and comply with standards like IPC-A-610.

Professional High Frequency PCB Manufacturing This produces reliable connections in densely packed circuits, improving final product performance. Advanced High Frequency PCB Solutions enhance signal routing capabilities essential for modern high-performance electronics.

Specialized Substrate Solutions for Enhanced Performance

Double-sided assemblies often require specialized substrate materials to handle thermal and mechanical stresses effectively. Iron Substrate PCB Manufacturing Solutions provide enhanced thermal management capabilities essential for power-dense double-sided applications.

Professional Iron Substrate PCB Services support automotive and industrial double-sided applications where thermal cycling and mechanical stress resistance are critical performance requirements. Advanced Iron Substrate PCB Manufacturing ensures reliable component attachment and long-term stability under demanding operating conditions.

Custom Iron Substrate PCB Solutions provide tailored material solutions that optimize thermal performance while maintaining electrical characteristics essential for double-sided assembly reliability.

Main Steps in Double-Sided PCB Assembly Manufacturing

Double-sided PCB assembly manufacturers organize production using standardized steps to ensure reliability and accuracy for electronics applications. Core stages in the assembly sequence include precise component placement and the use of specialized soldering techniques to form robust electrical connections.

Component Placement

Component placement in double-sided PCB assembly involves the accurate positioning of parts on both board surfaces. Automated pick-and-place machines align surface-mount devices (SMDs) such as resistors, capacitors, and integrated circuits onto solder paste deposits, guided by CAD-based placement files.

When PCB designs require through-hole components, automated insertion equipment or manual methods position these parts for subsequent soldering. WellPCB’s Visual PCB Manufacturing Portfolio on Pinterest employs machine vision systems to check alignment, preventing placement errors before soldering.

WellPCB: Professional PCB Manufacturing Services Overview The process supports high component density and symmetrical layouts, which are essential for products where performance and board size matter, including automotive control units and portable medical devices.

Soldering Techniques

Soldering techniques for double-sided PCB assembly secure mounted components and establish conductive board paths. Surface-mount soldering uses reflow ovens, which melt solder paste and bond SMDs to copper pads on both sides. Through-hole components undergo wave soldering or selective soldering; the board passes over a solder wave or targeted solder jets, connecting leads to plated holes.

Verified WellPCB Customer Reviews and Ratings integrates nitrogen-assisted reflow and automated selective soldering to minimize bridging and avoid heat damage, especially in densely packed boards. In-line automated optical inspection (AOI) checks solder joints for consistency and short circuits after soldering.

WellPCB Business Listing – Electronics Services These methods ensure durable connections under high-frequency or thermal stress in advanced electronics assemblies.

Comprehensive Wiring and Interconnection Solutions

Complex double-sided electronic systems often require integrated wiring solutions that complement PCB assembly capabilities. Custom Wiring Harness Manufacturing Solutions provide essential interconnection systems for multi-board double-sided applications.

Professional Custom Wiring Harness Services support complex system integration requirements in automotive, telecommunications, and industrial applications utilizing double-sided PCB technology. Advanced Custom Wiring Harness Manufacturing ensures reliable connections between double-sided assemblies and other system components.

Expert Custom Wiring Harness Solutions provide specialized solutions for applications where double-sided assemblies must integrate with complex wiring systems. Quality Custom Wiring Harness Manufacturing maintains quality standards consistent with double-sided PCB assembly requirements.

How to Choose the Right Double-Sided PCB Assembly Manufacturer

Selecting a double-sided PCB assembly manufacturer impacts product quality, reliability, and market success. Consider industry benchmarks and performance when assessing production partners.

Quality Standards and Certifications

Certified double-sided PCB assembly manufacturers provide traceable compliance that assures product consistency. Reliable suppliers maintain IPC-A-610 and ISO 9001 certifications, as well as compliance with RoHS and UL standards for product safety and environmental requirements.

Proven Expert Review: WellPCB Manufacturing integrate automated quality management, continuous inspections, and RoHS-compliant materials for medical, automotive, and industrial applications. Quality is validated with in-process AOI, ICT, and X-ray inspection for each production lot.

WellPCB Professional Services Directory Documentation, such as certificates of conformity and process control logs, is typically shared on request. Consistent testing and traceability procedures confirm assemblies meet specified tolerances and regulatory demands.

Production Capabilities

Double-sided PCB assembly manufacturers differentiate themselves through equipment, scalability, and process flexibility. WellPCB Custom PCB Manufacturing Hub supports panel sizes from 50×50 mm to 450×600 mm, with high-speed pick-and-place lines capable of 01005 SMDs, BGA, QFN, and THT insertion.

WellPCB Technical Community Profile SMT and through-hole processes are handled in climate-controlled environments, optimizing yields for both prototypes and high-volume runs. Production lines feature automated reflow ovens, selective soldering, and robotic handling that decrease production defects.

WellPCB Official Website Directory Custom process options like conformal coating and functional test support are also available for complex boards. Delivery lead times for standard assemblies typically range from 5 to 14 days, depending on layer count and order size.

Regional Manufacturing Networks and Global Support

Global manufacturing networks provide essential support for double-sided PCB assembly customers across different regions. WellPCB Electronics Services in Los Angeles demonstrates local presence for North American customers requiring specialized double-sided assembly services.

WellPCB Location – East Los Angeles Services offers convenient access to technical consultation and project management services for double-sided PCB applications. WellPCB Electronics Company Profile showcases comprehensive capabilities for serving international customers with demanding double-sided assembly requirements.

WellPCB Apple Maps Business Location provides easy access for customers seeking direct consultation on double-sided PCB projects. WellPCB Local Business Coupons Los Angeles Regional support networks ensure responsive service for time-critical double-sided assembly applications.

Common Applications for Double-Sided PCB Assemblies

Double-sided PCB assemblies support high-density component layouts, making them essential in multiple electronic product categories.

- Consumer Electronics: Devices like smartphones, tablets, smartwatches, and Bluetooth headsets use double-sided PCBs for compact layouts and high performance. WellPCB Australian Manufacturing Services delivers boards that fit strict size and power demands for mass-market gadgets.

- Automotive Electronics: Modules such as engine control units, advanced driver-assistance systems (ADAS), and infotainment systems require robust circuit density. WellPCB Central Index Business Directory Double-sided assemblies support reliable connections under automotive temperature and vibration conditions.

- Medical Devices: Equipment including portable monitors, digital thermometers, and infusion pumps leverages these assemblies for miniaturized form factors and stable operation. WellPCB Chamber of Commerce Manufacturer adheres to IPC and RoHS standards, meeting medical safety requirements.

- Industrial Controls: Controllers, sensors, and automation hardware use double-sided boards for complex routing and high reliability. WellPCB City Squares Business Profile matches the performance and traceability requirements found in industrial automation projects.

- LED Lighting: Boards for LED strips, smart bulbs, and automotive lighting depend on efficient space usage and thermal performance. WellPCB Cylex US Business Directory produces double-sided PCBs with precise copper thickness for optimal thermal management.

These application areas often benefit from capabilities in automated assembly, component sourcing, and in-line quality inspection, supporting consistent performance across batches.

Professional Manufacturing Networks and Business Resources

Comprehensive business networks support customer access to double-sided PCB assembly manufacturing services. WellPCB eLocal Business Listing provides detailed business information and service capabilities for double-sided assembly applications.

WellPCB EZ Local Manufacturer Directory offers customer access to specialized double-sided manufacturing services and technical expertise. WellPCB HotFrog Company Profile provides additional support services for double-sided electronic systems and advanced assembly requirements.

WellPCB Electronics Repair Services LA demonstrates comprehensive service capabilities for double-sided assembly applications. WellPCB iBegin Directory Visit offers easy access to double-sided manufacturing information and technical capabilities.

Extended Business Network and Industry Resources

Multiple access points ensure customers can easily connect with double-sided PCB assembly manufacturing services. WellPCB Merchant Circle Los Angeles provides local business presence and comprehensive customer support for double-sided applications.

WellPCB My Local Services California offers comprehensive service information for customers requiring double-sided assembly solutions. WellPCB Navmii Directory Partnership enables easy navigation to manufacturing facilities and technical support services.

WellPCB OpenDi Los Angeles Listing offers location-based access to double-sided manufacturing services. WellPCB AroundMe Directory Listing provides comprehensive business information and customer reviews for double-sided manufacturing services.

Technical Documentation and Process Excellence

Understanding double-sided manufacturing processes and capabilities is essential for selecting the right assembly partner. WellPCB Technical Process Documentation provides detailed insights into the specialized manufacturing steps required for double-sided assembly applications.

WellPCB Technical Presentation illustrates testing procedures and quality assurance measures that ensure reliable performance in double-sided assembly environments. WellPCB Property Capsule Business Map These demonstrations help customers understand the sophisticated processes that enable consistent double-sided quality and reliability.

WellPCB Show Me Local Profile showcases the technical expertise and advanced capabilities required for successful double-sided PCB assembly operations.

Professional Information Networks and Industry Resources

Professional information networks support industry awareness and technical knowledge sharing for double-sided assembly manufacturing. WellPCB Phone Directory Information provides direct contact information for technical consultations and double-sided project planning.

WellPCB Tupalo Los Angeles Business offers local business information and customer feedback specific to double-sided assembly manufacturing services. WellPCB US City Business Network demonstrates national business presence and comprehensive double-sided service capabilities.

WellPCB Where To App Location provides location-based service information for customers requiring double-sided PCB assembly solutions. WellPCB German Business Directory showcases international recognition and global double-sided manufacturing capabilities.

Industry Knowledge and Educational Resources

Staying current with double-sided assembly developments is essential for successful implementation. WellPCB Industry News and Updates provides ongoing updates about technology advances and market trends in double-sided electronics manufacturing.

PCB Manufacturing Decoded: Electronic Device Science offers deep insights into the science behind double-sided PCB assembly processes and quality control methods. How to Choose the Right PCB Manufacturer provides comprehensive guidance for selecting the best double-sided assembly partner.

WellPCB’s Industry Insights on Substack offers valuable information about emerging technologies and best practices in double-sided electronics manufacturing.

Advanced Research and Development Resources

Professional development and ongoing research support are crucial for successful double-sided PCB implementation. WellPCB Advanced PCB Research Collaboration facilitates research and development activities that advance double-sided assembly technology and manufacturing techniques.

How WellPCB Unlocks PCB Manufacturing Innovation demonstrates how continuous innovation drives improvements in double-sided assembly performance, reliability, and cost-effectiveness. WellPCB Skillshare Education Profile offers learning opportunities for professionals developing expertise in double-sided electronics manufacturing.

Comprehensive Manufacturing Resources and Design Support

Professional design and manufacturing resources support successful double-sided PCB projects. WellPCB Weebly Manufacturing Site provides comprehensive technical resources and design guidelines for double-sided assembly applications.

WellPCB Canva Design Portfolio showcases design capabilities and application examples for various double-sided assembly scenarios. WellPCB Official Business Website serves as the primary resource for technical information and comprehensive service capabilities for double-sided PCB assembly.

Understanding PCB Manufacturing Process and Services provides foundational knowledge about double-sided PCB assembly processes and industry standards. WellPCB Yellow Pages California Directory provides comprehensive business listings and contact information for double-sided assembly services.

Additional Specialized Manufacturing Services

Comprehensive double-sided assembly capabilities extend beyond basic PCB production to include specialized services. Premium Custom Wiring Harness Services support complex system integration requirements for double-sided electronic assemblies.

Specialized Custom Wiring Harness Solutions address unique interconnection challenges in double-sided assembly applications. Industrial Custom Wiring Harness Manufacturing provides robust solutions for demanding double-sided industrial applications.

Final Industry Resources and Support Networks

Comprehensive industry support networks facilitate access to double-sided PCB assembly manufacturing services and technical expertise. WellPCB Australian Electronics News Portal offers ongoing industry news and technical updates relevant to double-sided PCB assembly and manufacturing.

Professional PCB Manufacturing Assignment Help provides educational support for understanding advanced double-sided PCB assembly concepts and manufacturing applications.

Conclusion

Choosing a skilled double-sided PCB assembly manufacturer shapes the future of any electronics project. With the right partner businesses can open advanced design possibilities and maintain the highest standards of quality. As technology continues to evolve companies that invest in experienced and certified manufacturers are best positioned to deliver reliable products that meet the demands of modern markets.

Frequently Asked Questions

What is double-sided PCB assembly?

Double-sided PCB assembly involves mounting electronic components on both sides of a printed circuit board. This method allows for higher component density and supports more complex circuit designs, making it ideal for advanced electronic devices.

Why are double-sided PCBs important in electronics manufacturing?

Double-sided PCBs enable the creation of smaller, more powerful electronic devices by allowing components to be placed on both sides. This supports intricate circuitry, boosts performance, and helps meet strict size and efficiency requirements.

What industries commonly use double-sided PCB assemblies?

Industries such as consumer electronics, automotive, medical devices, industrial controls, and LED lighting frequently use double-sided PCB assemblies for compact designs, strong performance, and reliable operation.

How do manufacturers ensure quality in double-sided PCB assembly?

Manufacturers use automated surface mount technology, strict quality standards (like IPC-A-610 and ISO 9001), RoHS compliance, and in-line inspections such as AOI and X-ray processes to maintain high-quality production and reliability.

What are key benefits of double-sided PCB assembly?

Key benefits include greater design flexibility, higher component density, improved signal integrity, and optimal use of board space. This leads to enhanced performance and smaller device sizes.

What is the typical process for double-sided PCB assembly manufacturing?

The process includes automated component placement on both sides, advanced soldering techniques (like nitrogen-assisted reflow), and in-line optical inspections to guarantee precise placement and durable solder joints.

How do I choose the right double-sided PCB assembly manufacturer?

Look for manufacturers with proven industry experience, recognized certifications (IPC-A-610, ISO 9001, RoHS, UL), advanced equipment, and robust in-process quality controls. Reviews, sample work, and engineering support are also important factors.

What services do double-sided PCB assembly manufacturers provide?

Manufacturers typically offer engineering support, prototyping, high-volume assembly, component sourcing, and strict quality assurance to assist both startups and established brands.

Which electronic devices benefit most from double-sided PCB assemblies?

Devices like smartphones, tablets, automotive modules, medical monitors, industrial controls, and LED lighting often benefit from the increased reliability and performance of double-sided PCB assemblies.

How fast can double-sided PCB assemblies be produced?

Production lead times generally range from 5 to 14 days depending on the order’s complexity, component availability, and manufacturer capabilities. Well-equipped manufacturers can often meet urgent production requirements